Cast Iron Submersible Pumps made with Premium Quality Raw Material

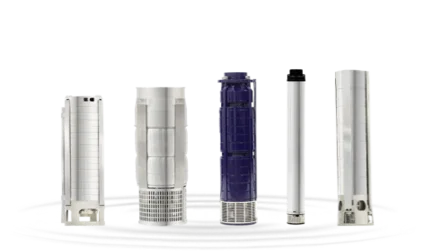

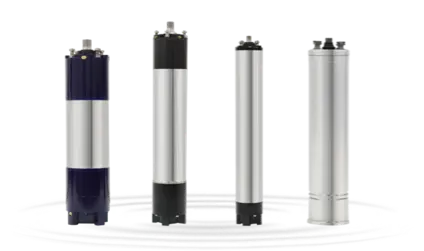

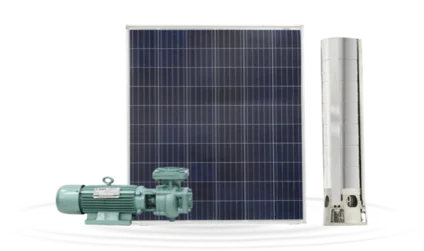

We bring a collection of durable and high-performance cast iron submersible pumps to cater to our clients’ varying needs. We followed international standards when manufacturing all components to offer reliable and energy-efficient pumps to our clients that last for years. All our pumps are fitted with non-return valves to prevent backflow as soon as the pump stops. These valves reduce the risk of water hammer as they have a short closing time. We have 4”-10” cast-iron submersible pumps to cater to our clients’ varying needs.

We used computational fluid dynamics when manufacturing all our pumps to ensure the highest level of efficiency. We used advanced CNC machines to manufacture all the components. It ensures longevity as well as high dimensional accuracy. A stainless-steel casing provides the shaft with protection. You can easily replace the shaft when it wears out. Our cast-iron submersible pumps are ideal for irrigation, water supply, firefighting, and civil and industrial sectors.

What is Cast Iron?

Cast iron is an alloy of iron that contains 2%-4% per cent of carbon alongside silicon and manganese in different proportions and trace levels of impurities in the form of phosphorus or Sulphur. It has become a popular engineering material due to having low melting temperature. This material has excellent machinability and fluidity due to this reason. It can be easily cast in different shapes. Its resistance to wearing, deformity and weakening due to oxidation makes it suitable for various applications. This alloy material is used to manufacture machines, pipes or parts used in the automotive industry, such as cylinder heads, gearbox cases or cylinder blocks.

Features of Cast Iron Submersible Pumps

- Pumps are fitted with individually balanced impellers.

- The materials that work with the sand found in Borewell are used in the pump.

- Computational fluid dynamics are used to design the pumps for maximum efficiency.

- A low friction non-return valve is used on all pumps to reduce the risk of water-hammer when it stops running.

- Stainless steel on all bronze impellers prevents abrasion caused by the sand found in Borewell.

- You can easily replace the stainless-steel casing that protects the shaft if it wears out.

- The up-thrust bearings control the axial movement of the impeller assembly when the pump starts running or during transportation.

- Advanced CNC machines are used to design all components to ensure the dimensional accuracy and longevity of the pump.

- Nitrile rubber is used to manufacture impeller wear-rings and journal bearings to ensure the stable performance of a pump over a period of time.

Product Range of Submersible Pumps

6” Cast Iron Submersible Pumps

We, Unnati Pumps Pvt Ltd. deliver robust and superior quality 6-inch iron submersible pumps that ensure higher efficiency and consistency in low-cost operation.

View Product8” Cast iron Submersible Pumps

We offer energy-efficient, high-quality and affordable 8” cast iron submersible pumps. Our v8 product is one of the best performing and on-demand submersible pump models among the clients.

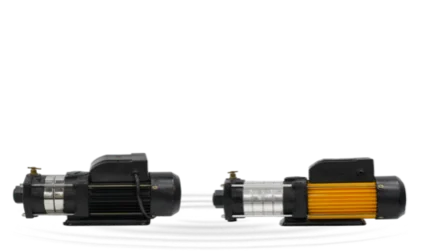

View ProductApplications

- Agriculture

- Construction & Building

- Industrial