Unnati Pumps - Global Leader in Submersible Pumps

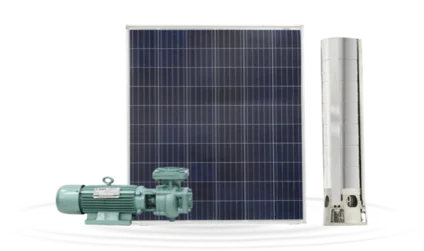

Looking for the best submersible water pump for your agricultural, industrial, or residential needs? Unnati Pumps is a top-rated submersible pump manufacturer and exporter based in India, delivering high-efficiency solutions for water lifting and fluid management. As a trusted global supplier, we offer a wide range of borewell pumps engineered for durability, performance, and long-term reliability. From deep-well irrigation to complex water systems, Unnati is your partner in precision pumping solutions

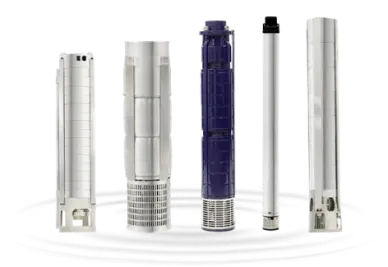

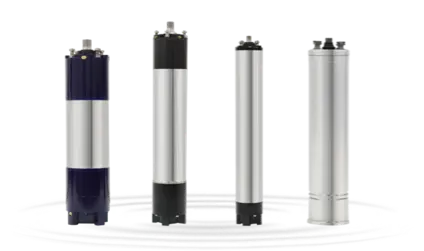

At Unnati Pumps, we combine sophisticated technology with modern manufacturing processes to deliver both international submersible water pumps and domestic submersible well pumps that are built to last. Our product range includes pumps from 75 mm (3″) to 250 mm (10″) with power capacities ranging from 0.5 HP to 150 HP, ensuring solutions for various applications and depths. Each well pump is constructed with high-quality components, including precision-engineered impellers, diffusers, cable guards, and submersible electric cables, ensuring long-lasting performance and efficient water delivery even under demanding conditions.

Why We’re the Best Submersible Pump Company in India

Unnati Pumps has earned its reputation through consistent quality, robust engineering, and a customer-first approach. Here’s what makes us one of the top submersible pump manufacturers:

- High-Efficiency Performance: Our pumps deliver excellent flow rates while conserving power.

- Reliable Manufacturing: Using the finest-grade stainless steel, virgin copper windings, and precision-molded impellers.

- Wide Range of Sizes: From 75 mm to 250 mm (0.5 HP to 150 HP) to meet any capacity demand.

- Custom Engineering: Tailored designs based on head, discharge, and site conditions.

- Proven Export Record: We’re a well-known submersible pump exporter, delivering globally with full support.

- After-Sales Support: Comprehensive service for both domestic and international clients.

Applications of Our Submersible Pump for Water

In many regions around the world, especially areas with limited surface water sources or inconsistent rainfall, well water pumps are essential for accessing groundwater. Borewell submersible pumps are specifically designed for this purpose—they remain fully submerged in water and are sealed to operate safely and efficiently under pressure. These pumps offer a reliable solution for drawing clean water from deep wells, making them ideal for agricultural, residential, and industrial use across diverse environments.

- Borewell Water Extraction (deep and shallow wells)

- Farm Irrigation & Drip Systems

- Water Supply for Buildings & Apartments

- Fire Protection Systems

- Sewage & Drainage Water Pumping

- Industrial Water Transfer

Need the best submersible water well pump? We’ll help you choose the right model based on your well depth, discharge needs, and local conditions.

Factors to Consider while Buying Submersible Pumps

Choosing the right submersible pump is essential for achieving optimal performance and long-term reliability. Whether you’re investing in a borewell submersible pump for agricultural irrigation or a submersible pump for water supply in residential or industrial settings, the following factors should guide your selection:

Size of Borewell

The diameter of your borewell determines what size borewell submersible pump can be installed. It’s important to select a pump with an outer diameter smaller than the borewell casing. A mismatch can prevent proper installation and may damage the pump or the borewell walls.

Head

It is the height to which a submersible pump can lift the groundwater. A customer has to select the correct model of pump based upon the size of the house and the water table of the area where a pump will be installed. TDH (Total Dynamic Head) is calculated by adding the head length, pumping level, drop-pipe friction loss and check-valve friction. It is measured in feet or meters.

Delivery Size/Outlet

It is the diameter of the pipe that is used in order to discharge the water from the pump. This diameter is measured in inches or millimetres. It has to match the size of the pipe that is connected to the storage tank.

Discharge Rate

It is the volume of water (measured in litre/minute or hour) that can be pumped by a Borewell submersible pump per minute. A pump of large discharge capacity will be required in a large area.

Stage

All of our pumps come with an efficiency chart. Selecting the correct stages of a pump based on its head and motor rating is essential for maximum efficiency.

Cooling System

Submersible pumps are available with either water-filled or oil-filled motors. Water-filled motors use water as a coolant, which can be refilled as needed. Oil-filled motors are sealed and more economical but not refillable. The right choice depends on your operating environment and maintenance preferences.

Construction Material

A product’s durability depends largely upon the construction material. The pumps made of Noryl impeller and CI motor body are the most durable in the collection.

Advantages of Using a Submersible Pump

Investing in a high-quality submersible pump for water comes with several operational and efficiency benefits. Here are the key advantages:

- No Need for Priming: A major benefit of a submersible pump is that it remains completely submerged in the water source, eliminating the need for manual priming. This also reduces the risk of airlocks or dry runs that could otherwise damage the internal components of the pump.

- Better Efficiency: Submersible water pumps are designed to operate under the water surface, where fluid pressure assists in water movement. This allows them to draw water more efficiently, reducing energy consumption compared to surface pumps.

- Anytime Function: A borewell submersible pump allows for water extraction at any time, offering consistent supply without depending on water pressure or time constraints. This makes it ideal for residential buildings, farms, and commercial operations that require round-the-clock access.

- NRV (Non-Return Valve): All our submersible pumps are equipped with a Non-Return Valve (NRV) to prevent backflow, ensuring stable water pressure and protecting the motor. Available in both single-phase and three-phase options, our models are tailored to suit different power ratings and installation conditions.

Submersible pumps perform and last longer when they are installed correctly. We strongly recommend ensuring the pump is fully submerged in water inside the borewell. Operating a pump without adequate water coverage can lead to overheating and significantly reduce its durability.

Explore & Buy the Best Submersible Well Pump

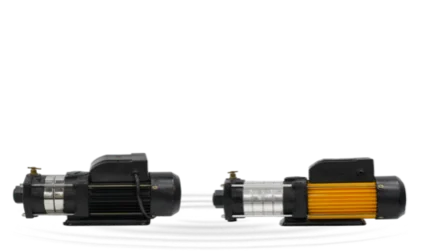

Unnati Pumps is your reliable partner for a high-quality submersible pump supplier tailored to a wide range of water pumping needs. Our extensive product lineup is engineered to serve a variety of applications from residential water supply and agricultural irrigation to demanding industrial uses. From the best submersible well pump to high-capacity systems designed for lifting large volumes of water, we offer reliable solutions to meet every need.

Product Range of Our Pumps

Stainless Steel Submersible Pumps

All our products are known for durability and high performance. However, no other material can withstand the brunt of acid, solvent, seawater and other chemicals as effectively as stainless steel.

View ProductCast Iron Submersible Pumps

We bring a collection of durable and high-performance cast iron submersible pumps to cater to our clients’ varying needs.

View ProductNoryl Submersible Pumps

With high stiffness and excellent tensile as well as flexural strength, Noryl is an ideal choice of material when manufacturing durable and efficient submersible pumps.

View ProductTop Selling Product of Submersible Pumps

Applications

- Agriculture

- Domestic

- Construction & Building

- Industrial